With climate change and other environmental issues seldom out of the headlines, more and more consumers are now looking for plant-based alternatives to their traditional meat-based food choices. Introducing: 3D bioprinting.

Restaurants can’t afford to ignore this trend, particularly if they want to attract the commercially critical Millennials and Generation Zers.

Increasing numbers are turning vegetarian or vegan, but it’s no longer going to be enough to offer them traditional nut roasts or bland tasting soy products.

What Today’s Customers are Demanding

What they want is to enjoy the taste of meat, but in the knowledge that no animal or habitat has been harmed by their choice.

That’s where 3D Bioprinting comes in.

KFC is just one major brand experimenting with this new restaurant technology as a way of reproducing the flavor of its signature offering in a more environmentally friendly way.

Already it’s successfully launched plant-based “chicken” in more than 50 California restaurants.

And China, the UK, Holland, and Canada are just a few of the nations around the world in which customers are also enjoying this technology.

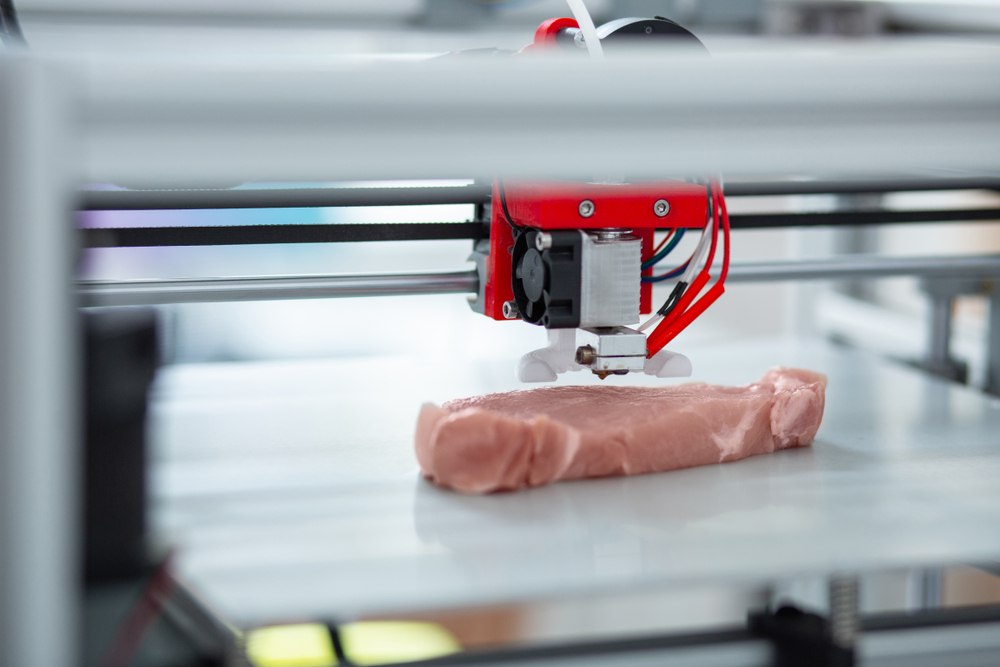

How 3D Bioprinting Works

Essentially, 3D Bioprinting involves the combining of small numbers of animal cells – obviously chicken, in the case of KFC – with plant materials such as grains, soy, pea protein, and vegetables.

The key point is that the animal cells are grown in a laboratory setting, avoiding the rearing and mass slaughter of live animals, the use of huge amounts of land for feed, and the administration of potentially harmful antibiotics.

Laboratory-grown meat is also free of the other additives that were thought essential in traditional farming – giving a purer, cleaner outcome.

But perhaps most importantly from the consumer’s point of view, the taste and texture of the original meat product can be replicated almost exactly by the addition of the relevant spices and seasonings.

The Environmental Case

Environmentalist studies suggest that laboratory production of meat cells may reduce greenhouse gas emissions by a factor of 25, and the use of land by a factor of 100. Energy consumption may be halved.

And while the use of any animal cells at all may put these bio-engineered products off-limits for the strictest of vegans or vegetarians, their environmental advantages will surely be attractive to many customers.

3D Printing In-House

This is a new and rapidly developing technology, which is by no means limited to finding alternatives to meat products.

Already machines are available to restaurants that can print a wide variety of pizza and pasta shapes, sauces, chocolate, and ice cream.

Essentially, these work by layering different ingredients and producing a 3D form designed by the user.

A huge range of ingredients can be used, and although these printers don’t yet cook the food, this development may not be too long away.

The Future

The bottom line is that these devices offer suitably trained and experienced staff a great way of providing customers with a new and creatively engaging experience – exactly what will be required to attract and retain them in the competitive post-pandemic world.